FAQ's

What is WPC?

WPC or Wood Plastic Composite is a blend of wood fibre, recycled thermoplastics plastics (PE, PP & PVC) and adhesive resins, UV stabilizers and colour pigments. This blend results in what is today considered one of most versatile & durable outdoor material replacing wood.

WPC has the appearance of wood with superlative inherent characteristics of high specific gravity, strength and dimensional stability. UV stability, colour fastness, water & termite resistance make WPC a material with one of the fastest growing market shares globally. Developing technology over the last decade has greatly improved the quality of WPC produced and the present generation is a product of highly refined manufacturing methods.

Most importantly, WPC is environment friendly since 90% of raw material is recovered from waste.

Why WPC Celuka?

WPC Boards are the best alternate for the traditional use of wood and plywood for its durability and thermoplastic for its flexibility. WPC Boards are the overcome of the entire problem faced with the plywood.

WPC Board have features such as highly resistant to extreme weather, moisture and termites and low maintenance. WPC Board Product won’t rot, crack, warp or splinter (as long as installed and used as recommended) meaning you can rest easy for years.

Is WPC Safe?

WPC production is a 100% safe manufacturing practice, releasing no air and water pollution and having no process waste of materials. The production waste can also be recycled into top quality product again.WPC is a highly eco-friendly product having no formaldehyde emission.

What other materials are reinforced to process WPC?

Timber import is increasing day by day and lot of waste is also being generated in volumes. This waste is coming out of saw mills, plywood mills, veneer units, Particleboard units, MDF units as well as from good quality agriculture residues like Cotton stalks, Sugarcane bagasse, Coir fibers and even Rice husk..

What are the possible surface treatments, which can be done on WPC Boards?

- Laminates can easily be pasted on WPC Boards

- Veneers can easily be pasted on WPC Boards

- High Gloss, Matt, Satin P.U Paint surface can be prepared with less consumption of material.

- ACP’s and Acrylic solid surface can also be cladded on the same.

- Lacquer finish

- All Routing and Carving Possibilities

How are WPC Boards most technologically advanced?

WPC Boards are not just single layer wood polymer composite boards. Infact at WPC, boards are prepared using the Multi-layer Technology. In this technology, there are 3 significant layers are visible which gives it a look and feel of pre laminated boards.

What is the guarantee of the WPC Boards?

WPC Boards offers Lifetime guarantee for being:

- 100% formaldehyde and toxic free

- Any damage due to termite, pest, bacteria, fungus and boring insects

- Any damage caused due to exposure to water or moisture.

The material has been tested and has passed the requirements for all these aspects as per the international standards.

What are the color options in WPC Boards?

The color options are:

- Wood

- Coffee

- Brown

What grade of Polymers are used to manufacture WPC Boards?

Only Virgin grade thermo polymers are used to manufacture the WPC Boards, which makes it a Pure Green product.

Can we insert dowel and minifix in WPC Boards?

The Answer is YES, infact with more ease. In particle boards or MDF, u need to put some glue and dowel or minifix the same. However, in case of WPC, we can we don’t need to apply any adhesive.

What adhesives are used on WPC Boards for gluing laminates or veneers?

All water based adhesives (PVC to Wood) manufactured by Fevicol, Jowat (148.20) etc. can be used for pasting any laminate or veneer on surface of WPC Boards. The recommended glue is formaldehyde and solvent free.

Is there a need to sand before pasting any laminate or veneer on WPC Boards?

The smooth surface of WPC Boards makes it feel that, before applying any adhesive, we need to sand the surface!!! However, we don’t need to sand the surface as WPC Boards are manufactured using cross linking polymer technology, which ensures perfect and durable gluing of laminate to Board.

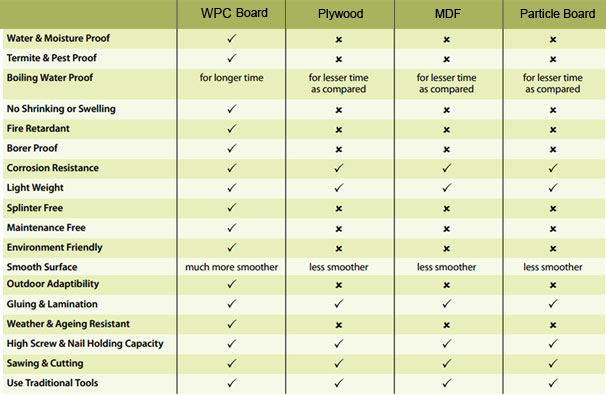

What is the comparison of WPC Boards to conventional wood based boards (Plywood, MDF and Particle Board)

Comparison of WPC Boards

What is the screwing or nailing strength in WPC Boards?

All types of screws and nails can be easily drilled or nailed with the help of conventional tools. When u screw on WPC Boards, then the sturdy combination of virgin polymers and dried wood fibres, insures that it forms a circular ring. Thus, even if u screw or unscrew at the same position for more than 10 times also, it doesn’t gets free. Moreover, any hardware once screwed will never become loose. Thus, WPC Boards